Quality

Helping You Achieve Excellence

We know how important quality is to you and your customers. That’s why we’ve developed a quality program that’s second-to-none.

At PremaTech, our quality policy is to meet or exceed the customer’s requirements by incorporating methodologies based upon sound scientific and engineering principles. The cornerstone of this policy is continuous improvement based upon the use of emerging technologies.

The activities we perform to make certain that all of our advanced ceramic components meet the tightest specifications include:

- First Article Approval Programs

- Optical & Video Measuring and Monitoring

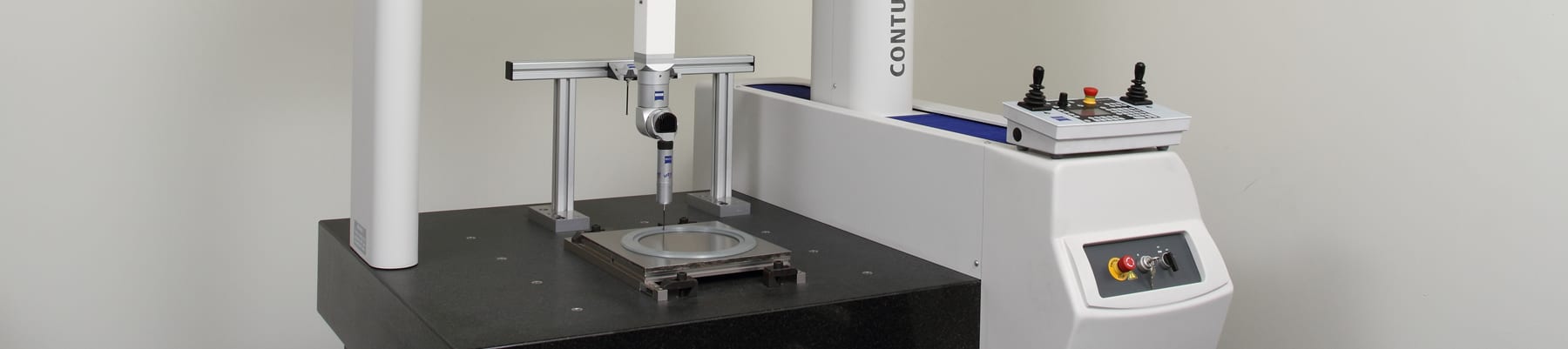

- Metrology Testing

Our Metrology Lab has a 12″ Interferometer, CMMs, Microscopes, White Light Interferometry and a clean, temperature-controlled environment.

We also have a central coolant recovery system, along with other modern equipment that helps us maximize our commitment to sustainable production, and the precision of every component we fabricate.

By applying science-based methods to our ISO 9001:2015 certified production management systems, we assure that your ceramic ground parts are made to the exact specifications.

Controlling Parts Conditioning & Cleaning

Our ISO Class 5 Cleanroom has the most modern cleaning and packaging equipment. This highly controlled environment enables us to monitor water quality and other elements of our processes. The cleanroom features:

- Ultra-Pure Water System

- Redundant Chemical Wet-Process Benches

- High Capacity Cleaning Stations to Accommodate Large Critical Parts